Diaphragm Seal Repair: What You Need to Know

Diaphragm seals are a critical component in many industrial applications, ensuring accurate pressure measurements and protecting instruments from harsh process conditions. However, like any mechanical component, they can wear out or fail over time. When this happens, businesses must decide whether to repair or replace the diaphragm seal.

Why Do Diaphragm Seals Need Repair?

The most common reason for repairing a diaphragm seal is when the instrument it’s attached to stops functioning properly. Since the diaphragm seal is an intermediary between the process and the measuring instrument, any failure in the seal can lead to inaccurate readings or even damage to the instrument itself.

The second most common reason is preventive maintenance during a routine shutdown. Many industries, especially those with high-precision measurement needs, use scheduled shutdowns to inspect, repair, and maintain critical equipment, including diaphragm seals.

Repair vs. Replace: Which is the Better Choice?

The decision to repair or replace a diaphragm seal comes down to two key factors: cost and time.

- Repairing a diaphragm seal is often faster and more cost-effective than ordering and installing a brand-new unit.

- Replacing a diaphragm seal may be necessary if the damage is extensive, if the model is obsolete, or if process conditions have changed, requiring an upgrade.

Why Choose Repair?

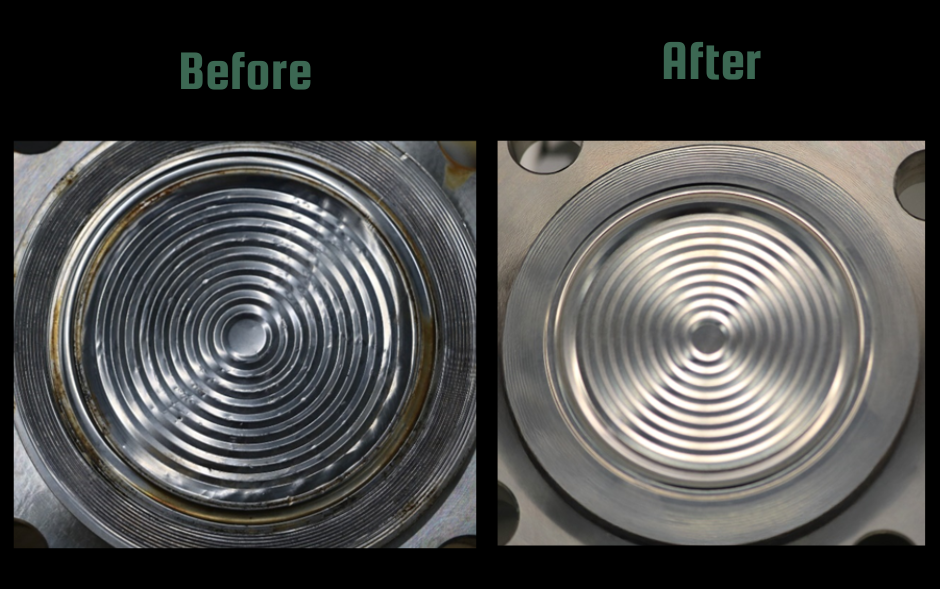

- Cost savings: Repairing a damaged diaphragm seal is usually less expensive than buying a new one.

- Faster turnaround: In many cases, a repaired seal can be returned to service quicker than waiting for a replacement, reducing downtime.

- Sustainability: Repairing extends the life of the existing equipment, minimizing waste and reducing the need for new materials.

Why Would a Diaphragm Seal Fail?

Diaphragm seals are exposed to extreme conditions, making them susceptible to various types of damage. The most common reasons for failure include:

- Physical damage – External forces, mishandling, or impact can cause dents, punctures, or misalignment.

- Loss of fill fluid – If the diaphragm seal loses its fill fluid due to a leak or seal failure, it will no longer transmit accurate pressure readings.

- Overpressure or over-temperature exposure – Exceeding the seal’s pressure or temperature limits can lead to deformation, loss of responsiveness, or complete failure.

- Corrosion – In aggressive chemical environments, diaphragm materials can degrade over time, affecting performance and durability.

Industries That Rely on Diaphragm Seal Repairs

Several industries depend on diaphragm seal repairs to maintain operational efficiency and ensure instrument reliability. Some of the most common include:

- Chemical plants – Harsh process conditions make diaphragm seal maintenance essential.

- Oil & gas – High-pressure environments demand frequent inspections and repairs.

- Pharmaceutical & food processing – Cleanliness and accuracy are crucial, requiring periodic diaphragm seal servicing.

- Cryogenic applications – Extreme temperatures necessitate regular maintenance to prevent failures.

Consequences of Using a Damaged Diaphragm Seal

Using a damaged diaphragm seal in industrial applications can lead to serious operational risks, including:

- Inaccurate pressure readings – Misleading data can result in improper process control, impacting product quality and safety.

- Potential damage to the instrument – A compromised diaphragm seal may expose the instrument to harsh process conditions, leading to costly repairs or replacements.

- Safety hazards – In industries dealing with hazardous substances, a malfunctioning seal can contribute to leaks or unsafe pressure levels.

Final Thoughts

When diaphragm seals fail, the decision to repair or replace depends on factors like cost, downtime, and the extent of the damage. In many cases, repairing a diaphragm seal is the most efficient and economical solution, allowing businesses to maintain their operations without unnecessary expenses or delays.

If you suspect your diaphragm seal is failing or needs maintenance, it’s best to act quickly to prevent further issues. Contact a trusted expert to evaluate your options and keep your systems running smoothly.