The Thermal Guardian®: Revolutionizing High-Temperature Pressure Measurement

In industries where extreme temperatures are a constant challenge, accurate pressure measurement is critical to maintain efficiency and safety. Many traditional diaphragm seals struggle to maintain performance in ultra-high temperatures, often leading to inaccurate readings, instrument failures, and costly downtime. That’s where Haygor Instrument’s Thermal Guardian® comes in a patented technology designed to withstand temperatures up to 1200°F (650°C) while maintaining precise pressure measurement and extending the life of pressure instruments.

What is the Thermal Guardian?

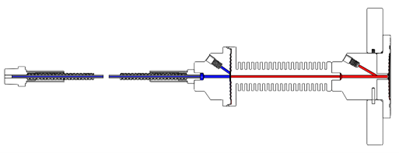

The Thermal Guardian® Diaphragm Seal is Haygor’s latest innovation in high-temperature pressure measurement technology. This patented device dissipates heat, acting as an additional thermal barrier between a standard diaphragm seal and the pressure instrument. Unlike traditional seals, which rely on silicon-based fill fluids that can break down at high temperatures, the Thermal Guardian uses our proprietary liquid metal alloy, including Galinstan®. This liquid metal remains stable across a wide temperature range, ensuring consistent and precise pressure readings without expansion, contraction, or degradation.

Key features of the Thermal Guardian include:

Key features of the Thermal Guardian include:

- Temperature Resistance: Can withstand continuous exposure to 1200°F (650°C).

- Enhanced Instrument Protection: Prevents overheating, which extends the life of pressure instruments.

- Oil-Free Design: Uses liquid metal instead of traditional silicon-based fluids, eliminating vaporization concerns.

- Seamless Integration: Available with direct mount or capillary mount diaphragm seal systems and compatible with gauge and differential pressure instruments.

- Material Flexibility: Constructed with 316L stainless steel, with options for exotic materials and secondary fill fluids.

Why Do You Need the Thermal Guardian?

For many industries, accurate pressure measurement at high temperatures is essential for maintaining process control and preventing equipment damage. The Thermal Guardian is a game-changer for companies operating in:

- Oil & Gas – Refinery processes involve extreme heat, making accurate pressure readings crucial for efficiency and safety.

- Chemical Processing – Many reactions and distillation processes require precise monitoring at elevated temperatures.

- Cryogenics – While cryogenic applications deal with extremely low temperatures, Thermal Guardian technology ensures high thermal stability across temperature fluctuations.

The Competitive Advantage

Haygor’s Thermal Guardian stands apart from competitors by offering continuous operation at 1200°F. Most competing diaphragm seals can only handle 850°F at peak temperatures, meaning they fail under prolonged exposure to extreme heat. With a quick turnaround time of just 5 days, Haygor ensures that businesses receive fast and reliable solutions to high-temperature measurement challenges.

How Does the Thermal Guardian Work?

The Thermal Guardian undergoes a rigorous high-temperature process to ensure maximum reliability. Here’s a breakdown of how it performs under extreme conditions:

- Installation & Integration

- The Thermal Guardian can be installed as part of a direct mount or capillary mount diaphragm seal system.

- It attaches to either gauge pressure or differential pressure instruments.

- Available with various wetted materials to match process requirements.

- Heat Dissipation & Protection

- When exposed to extreme temperatures (up to 1280°F in testing), the Thermal Guardian acts as a buffer, reducing heat transfer to the pressure instrument.

- The liquid metal fill remains stable, preventing thermal expansion and ensuring accurate pressure reading.

- Extended Performance Over Time

- Unlike conventional systems that degrade over time due to heat stress, the Thermal Guardian maintains precision for extended periods.

- Lab tests have shown an 800°F temperature drop across the Thermal Guardian’s structure, significantly reducing stress on the instrument.

- Repair & Upgrade Capabilities

- Existing diaphragm seals can be upgraded to the Thermal Guardian system, providing a cost-effective solution for companies looking to improve performance without replacing entire systems.

Is the Thermal Guardian Right for Your Application?

If you answer yes to any of the following questions, the Thermal Guardian is the ideal solution for your pressure measurement needs: Do you operate processes above 600°F (315°C) and struggle with accurate pressure readings?

- Do you need quick turnaround times for critical instrumentation?

- Are you looking for a long-lasting, repairable diaphragm seal system?

- Do you want to eliminate the risk of instrument failure due to excessive heat?

The Future of High-Temperature Pressure Measurement

Haygor Instrument’s Thermal Guardian® is a breakthrough technology for industries dealing with extreme temperatures. With its patented liquid metal technology, unmatched temperature resistance, and seamless integration with existing systems, it provides a reliable, long-term solution for precise pressure measurement in harsh environments.

Ready to upgrade your pressure measurement system? Contact Haygor Instrument today to learn more about how the Thermal Guardian can enhance your operations and protect your equipment from extreme temperatures.